Control units

For the VGE Pro UV-C systems, 6 different control units are available.

Benefits

- A control unit for every VGE Pro UV-C system

Technical specifications

VGE Pro Control units

Basic

The Basic version is suited with an electronic ballast to drive the lamp(s). Standard the power supply of the UV-C lamps is realized by electronic ballasts which drive the lamps with a much higher frequency (over 30,000 Hz) compared to conventional electromagnetic ballasts (50/60 Hz).

| Basic unit specifications: | Higher ballast efficiency, so less heat production |

|---|---|

| Longer lamp life of the UV-C lamps | |

| Higher UV-C lamp efficiency | |

| Direct start, no conventional ignitor required |

Control Timer

The Control Timer has a LED display for showing the operational lamp hours. The maximum number of burning hours are displayed when the system is started. After this the display counts down to 0, at which time the lamp must be replaced.

Hour counter

If a UV-C lamp is in operation natural aging of the lamp will take place which results in a reduction of UV-C radiation and disinfection capacity. Therefore it is important to replace a UV-C lamp in time. An operational hours counter is a useful tool to make sure that you change the UV-C lamp on time and keep up a reliable UV-C disinfection of your water

| Control Timer unit specifications: | LED display for showing the operational lamp hours |

|---|---|

| Maximum number of burning hours are displayed |

Control Monitor

The Control Monitor has a colour display and an optional UV sensor can be connected for monitoring the treatment process.

Several ways of communication with a control unit are available such as: analog 4 - 20 mA signal, via potential free contacts and of course via the HMI. By using these options the control of your disinfection process is easy and efficient.

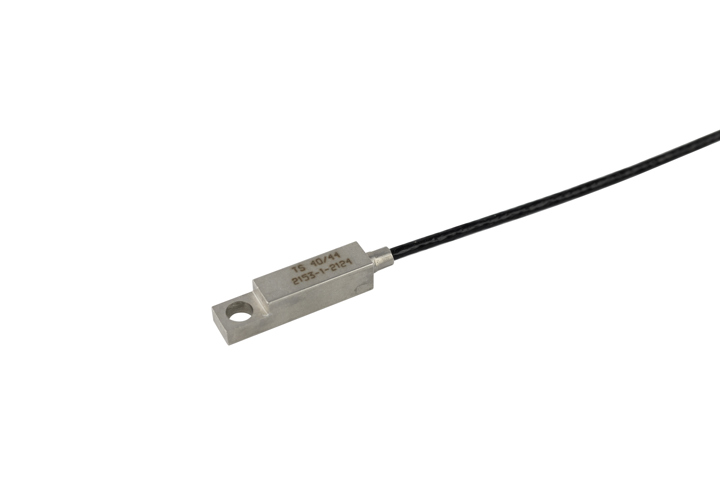

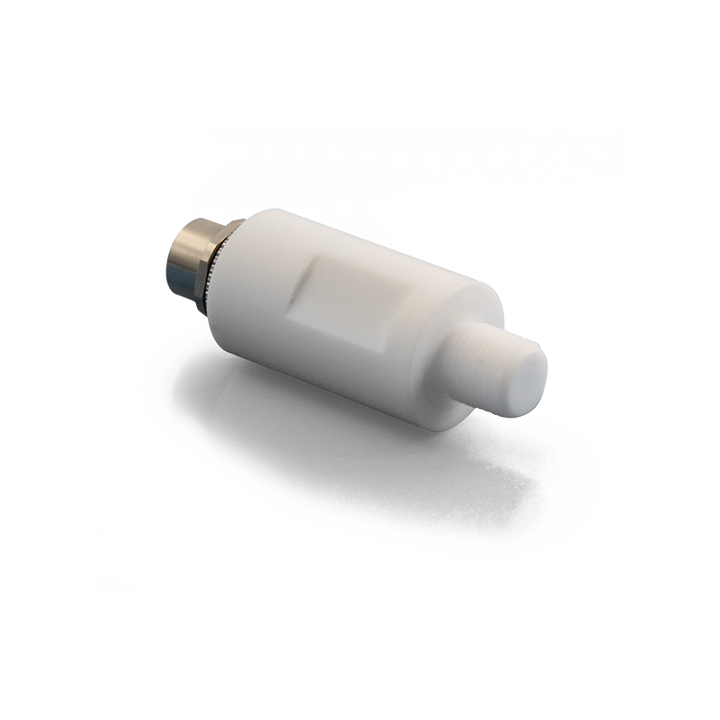

The monitor can measure the UV-C intensity inside the treatment chamber by adding a UV sensor. Depending on the application a certain UV-Cintensity must be realized for a reliable disinfection result. A flowswitch can be connected to switch off the UV-C system when there is no water flow through the treatment chamber. This to prevent malfunctioning of the system.

| Control Monitor unit specifications: | Colour display |

|---|---|

| Several ways of communication available | |

| Measures the UV-C intensity inside the treatment chamber | |

| A flowswitch can be connected |

Control Monitor Plus

The Control Monitor Plus is a complete controller and multilingual. A UV sensor, temperature sensor and a flowswitch can be connected. The control unit has alarm and warning functions built-in.

When there is no flow or water in the treatment chamber when the lamp is switched on, the temperature in the chamber can reach a dangerous level. By choosing the optional temperature sensor in combination with the Control Monitor Plus the temperature inside the treatment chamber is monitored. If the limit is reached the system will be switched off and an alarm will be activated.

| Control Monitor Plus unit specifications: | Complete controller and multilingual |

|---|---|

| UV sensor, temperature sensor and flowswitch can be connected | |

| Built-in alarm and warning functions |

Compact controller

The Compact controller is a basic controller, suitable for a MultiMax or 600-85 medium pressure UV lamp systems. It’s equipped with a LED lamp life indication.

Depending on the life of the lamp, the LED shows a different colour. Green means that the lamp is still burning properly. Flashing red means the lamp will need to be replaced soon. With a red LED lighting continuous, it means that the lamp must be replaced immediately.

| Compact controller unit specifications: | Green or red led - lamp life indication |

|---|---|

| Suitable for a MultiMax or 600-85 medium pressure UV lamp systems |

Comfort controller

The Comfort control box is a complete control box for the 600-85 to 3000-326 medium pressure units. The controller can optionally be equipped with a UV sensor to measure the UV-C intensity inside the treatment chamber. Besides that it is suitable for a temperature sensor. The temperature sensor monitors the temperature in the treatment chamber to avoid overheating. The display text on the controller is available with different languages.

| Comfort controller unit specifications: | Complete controller for the medium pressure lamp units |

|---|---|

| Can optionally be equipped with a UV sensor | |

| Suitable for a temperature sensor | |

| Available with different languages |

we are VGE PRO

Harmful pathogens are a scourge within the aquaculture industry and are often controlled with antibiotics. This has a negative impact on the water quality and thus also on the quality of the fish. As the aquaculture sector is growing every year, it becomes more important to reduce these pathogens in a sustainable way.

The answer for this is UV-C disinfection. UV-C disinfection is safe to use and protects against fish diseases without formation of any disinfection by products (DBPs) and ensures a higher survival rate. VGE Pro UV-C systems are therefore very cost-effective for the inactivation of many types of bacteria, viruses and parasites and provide healthy, clear and safe water.